Along with the rapid transition and challenges of global ecology, we human beings have to face the issue: how can we live in harmony with the nature? Recently, countries across the world have successively proposed their timetables for carbon neutrality and China also has committed to peaking carbon dioxide emissions by 2030 and achieving carbon neutrality by 2060.To realize these goals, the key factors lie in the energy transition in various industries. Electrifying the vehicles and engineering machinery is a quick and effective way of reducing the carbon emissions and promoting the green and sustainable development.

Supported by the national policies, the electrification of vehicles has developed dramatically in China from the initial commercial vehicles to passenger vehicles. Meanwhile, the powertrain system technologies and related products have become maturer and their costs have gradually been reduced, which make the core components like battery, motor and MCU more cost-effective and drives the application of electric powertrain technologies in engineering machinery fields.

IIIinois-based Caterpillar (CAT), established in 1925, is the biggest manufacturer of engineering machinery in the world owing to its accumulated technology and product advantages in the past 98 years. CAT owns many sub-brands worldwide and operates SEM and CAT in China. To meet the requirements of R&D and manufacturing for different types of engineering machinery, CAT built two R&D centers in Qingdao and Wuxi and multiple production bases in Shanghai, Suzhou, Wuxi, Tianjin, Shangdong, etc.

At the end of 2020, SEM took the lead in carrying out electrification on wheel loaders and the technical team in Wuxi R&D center put forward the request of customized products. GTAKE was selected because of its industry-leading technologies and high-quality products which not only meet the function requirements of wheel loaders, but also pass the rigorous performance tests.

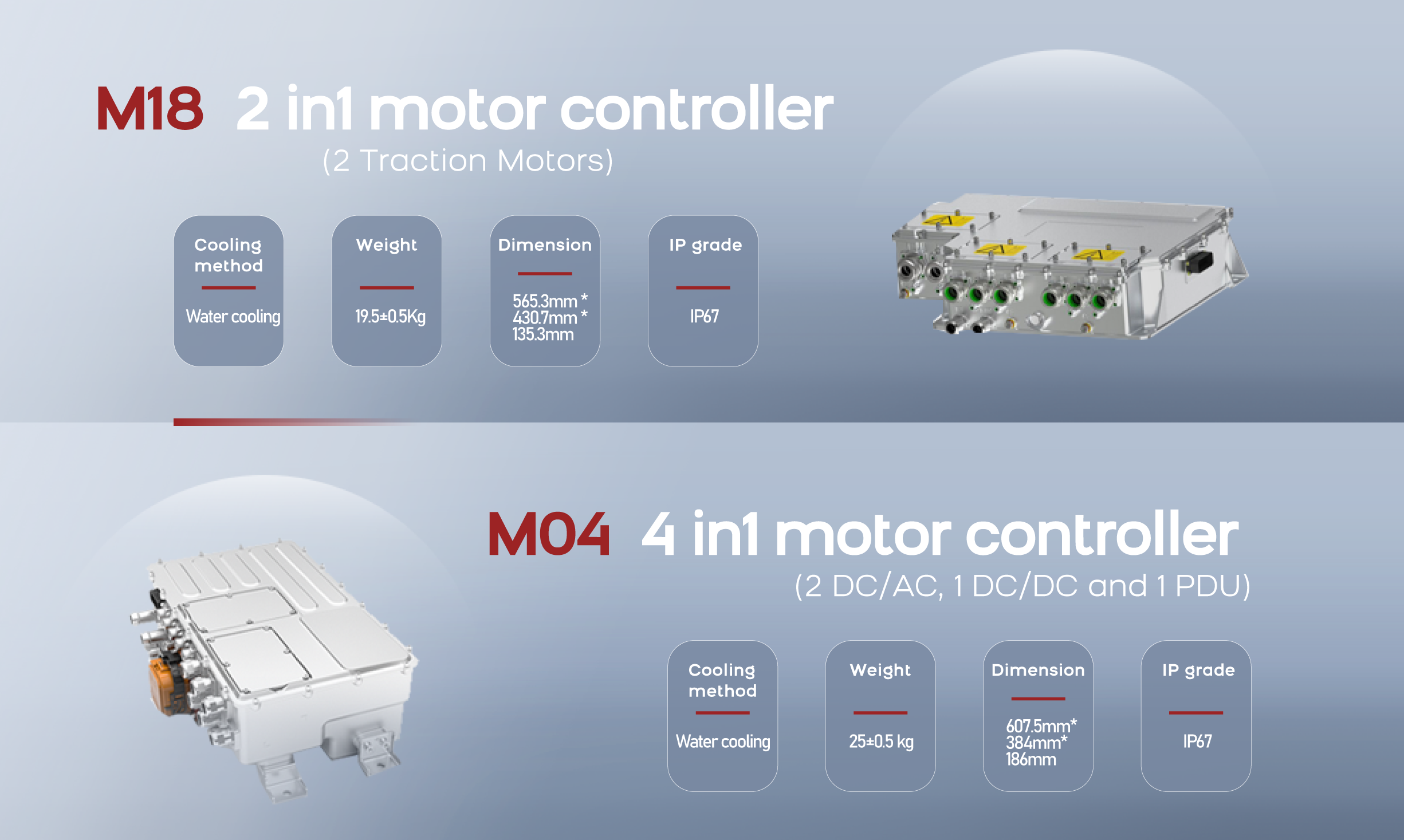

SEM wheel loader adopts M18 and M04 motor controllers which have intelligent temperature monitor system featuring stable power output and optimal heat dissipation. Equipped with the three-level current leakage protection, whose protection program can monitor the status all the time and automatically intervenes once being triggered, the motor controller can not only better ensure the safety of personnel and machine but also reduce the fault rate. As the wheel loader works in the harsh environment with a lot of dust, mud and sand, the IP67 housing of M18 and M04 facilitates the stable and reliable operation of wheel loaders, thus guaranteeing the progress of the project.

Until now, SEM has purchased MCUs from GTAKE several times and the electrified wheel loaders were delivered to the downstream customers. GTAKE MCUs have been sent to CAT headquarters in the US for in-depth and all-round tests. It’s expected that GTAKE MCUs will be promoted by CAT in its engineering machinery to meet the global market demands.

It is learnt that SEM electric wheel loaders will be massively produced in 2023 to meet the booming market demands and reduce the carbon emissions. GTAKE, as one of the suppliers of CAT, also provides the sophisticated EV/HEV motor controller solutions for its pushdozers and other engineering machinery. To protect the environment and cut down the carbon emissions, GTAKE is concentrated on exploring electrification for more applications and providing more outstanding products for customers worldwide.