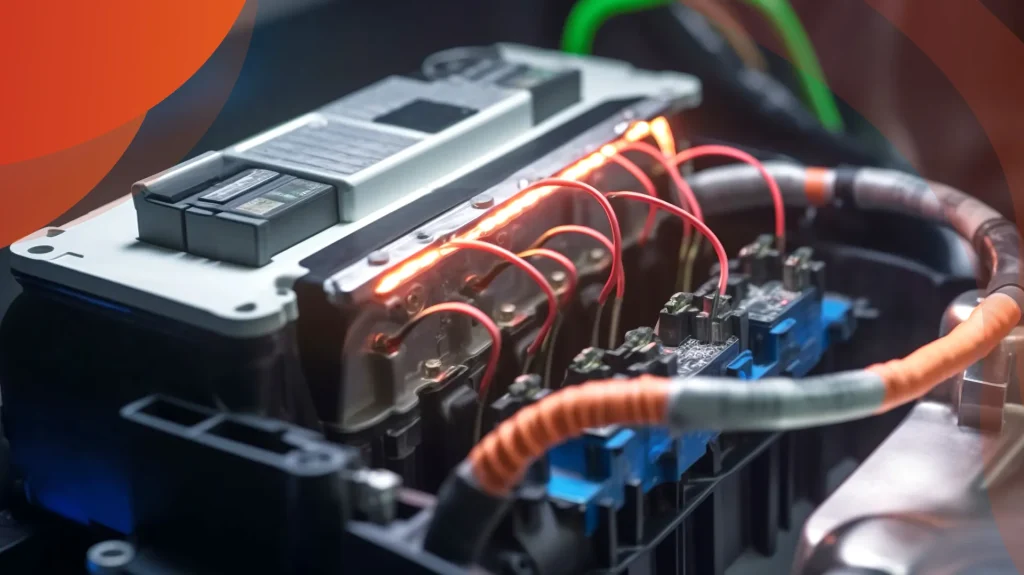

In electric motorcycle drive systems, the controller serves as a critical bridge between the motor and the battery. Its performance directly affects the vehicle’s power response, energy efficiency, and system stability. Within the power stage of the controller, the MOSFET (Metal-Oxide-Semiconductor Field-Effect Transistor) plays a central role, managing high-current switching to control motor operation.

The number of MOSFETs used in a motor controller significantly influences its maximum power output, thermal management, cost, physical size, and overall reliability. Understanding how MOSFET quantity impacts these factors — and how to optimize it — is essential for developing efficient and robust EV controllers.

Factors Affecting MOSFET Quantity

MOSFETs regulate current flow by performing high-frequency switching, thereby controlling motor speed and torque. Each MOSFET has a limit on its voltage and current handling capability. Therefore, to meet higher power demands, multiple MOSFETs are often connected in parallel.

Key factors that determine the required number of MOSFETs include:

- Controller Output Power Level: Higher power output requires greater current-handling capability, necessitating more MOSFETs.

- Current Sharing Design: Parallel MOSFETs reduce individual device stress, improving thermal performance and lifespan.

- Manufacturer Design Strategy: Different manufacturers may choose varying configurations based on cost, space, and efficiency considerations.

For example, low-power controllers used in e-bikes or scooters might only require dozens of MOSFETs, while high-power controllers for electric motorcycles or cars can use hundreds to ensure stable and reliable power delivery.

Performance Impacts of MOSFET Quantity

Increasing the number of MOSFETs generally offers several benefits:

- Higher Current Capacity: More devices in parallel distribute current evenly, reducing overheating and failure risks.

- Improved Thermal Management: Spreading heat across multiple components helps maintain thermal equilibrium and reduces strain on heatsinks.

- Enhanced System Redundancy: The loss of one or a few MOSFETs doesn’t immediately cause system failure, increasing controller reliability.

However, excessive MOSFET usage also introduces challenges:

- Increased PCB Complexity: More MOSFETs require intricate driver circuits and layout designs, which can affect long-term reliability.

- Greater Risk of Electrical Interference: With more parallel switches, EMI (Electromagnetic Interference) and signal coupling become concerns.

- Cost and Matching Issues: Large numbers of MOSFETs must be carefully matched to ensure even current sharing; otherwise, imbalances can lead to premature failures.

Thus, selecting the right number of MOSFETs involves balancing performance needs with design complexity and cost constraints.

Optimization Strategies for MOSFET Quantity

The optimal number of MOSFETs depends heavily on the application scenario:

- Urban Light Mobility Devices (e.g., E-Bikes): Prioritize lightweight design and cost-effectiveness. MOSFET count should be kept minimal without sacrificing basic performance.

- Mid-Power Scooters and Trikes: Balance performance and cost. A moderate number of parallel MOSFETs works best, with emphasis on thermal balance and heat dissipation.

- High-Speed Scooters: These systems handle high currents and torques. A larger number of MOSFETs is necessary, ideally combined with intelligent thermal management and current-sharing algorithms.

Designers can also leverage electrothermal simulation tools to model how different MOSFET counts affect efficiency and thermal behavior, enabling data-driven component selection.

Beware of the “More is Better” Myth

It’s important to recognize that more MOSFETs don’t always mean better performance. Controller performance is influenced by multiple factors, including:

- MOSFET Quality and Switching Characteristics (e.g., on-resistance, gate charge)

- Driver Circuit Speed and Symmetry

- Thermal Design and Enclosure Structure

- Control Algorithm Responsiveness and Precision

With advancements in semiconductor technology — especially the emergence of wide-bandgap materials like SiC (Silicon Carbide) — modern MOSFETs offer significantly improved performance. As a result, high-end controllers can now achieve high output with fewer transistors. When evaluating controllers, users should focus on system-level efficiency, stability, and technical support, rather than simply counting the number of MOSFETs.

Conclusion: Optimize MOSFET Configuration for Efficient Drive Systems

As a core component in electric motorcycle controllers, MOSFETs — both in terms of type and quantity — play a crucial role in determining system performance, reliability, and cost. By considering output power requirements, thermal performance, and electromagnetic compatibility, engineers can optimize MOSFET configuration to build stable, efficient, and cost-effective electric drive sys

Looking for Professional EV Controller Solutions?

GTAKE offers tailored controller systems designed for two-wheel and three-wheel electric vehicles, with a focus on thermal reliability, switching efficiency, and intelligent current control. Our team supports customers in optimizing MOSFET configurations to achieve robust and scalable designs.