With the continuous expansion of global trade and the rapid growth of cross-border transportation of energy and raw materials, the demand for large container ships, bulk carriers, and oil tankers has surged. To maintain efficient sailing speeds, these massive vessels rely on high-power engines, which have become the cornerstone of global trade and green shipping development. At the same time, the increasing power requirements place greater demands on engine R&D testing benches and their supporting electrical control systems.

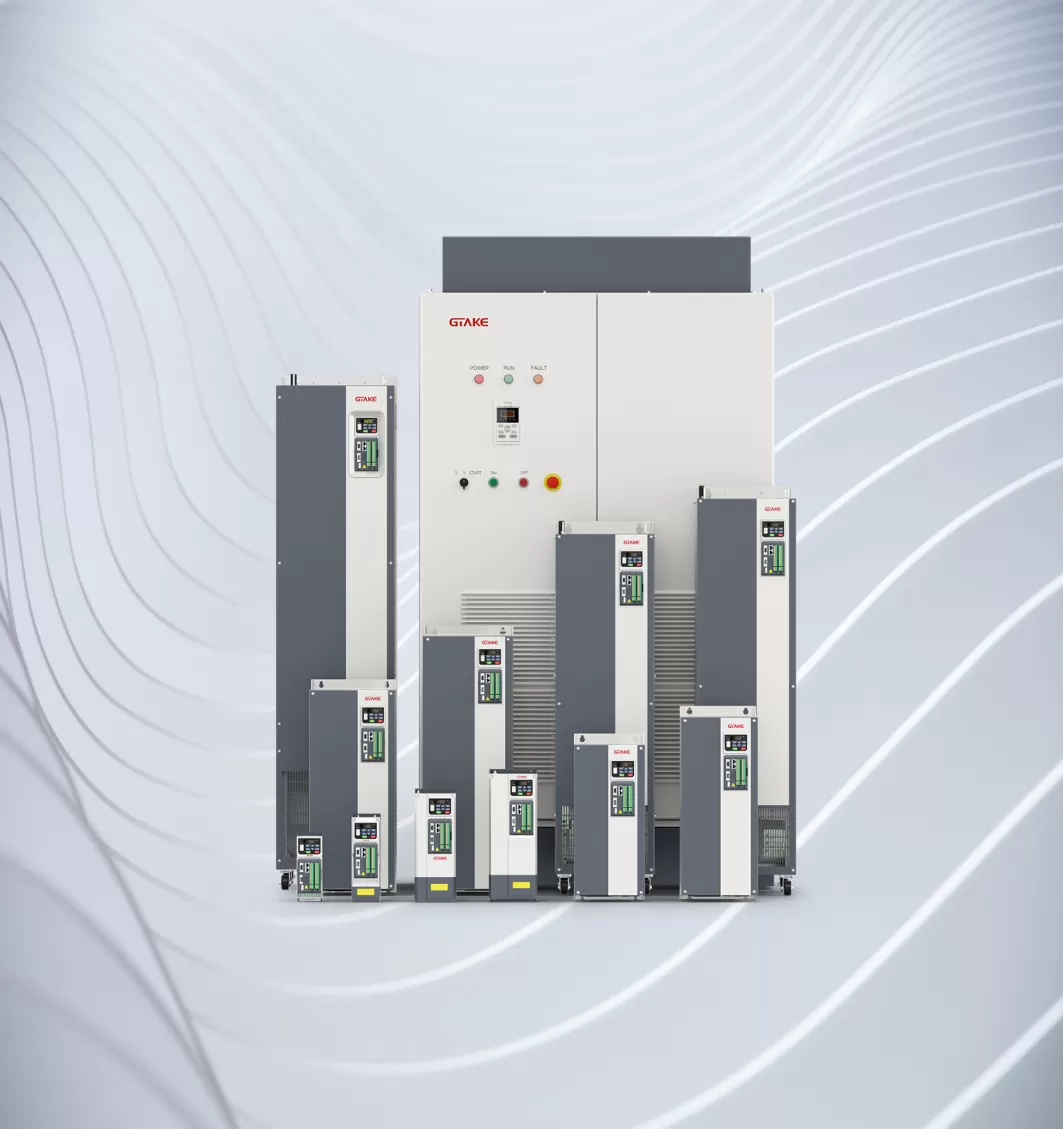

In this context, the GK980 multi-drive variable frequency drive (VFD) has been applied in a large-scale high-power test bench project, demonstrating excellent flexibility, stability, and compatibility.

High-Power Test Bench Control Scheme

The test bench adopts a multi-drive parallel structure designed to handle extreme power requirements. The system configuration includes:

- 8 × 500 kW AFE (Active Front-End) power units

- 9 × 500 kW inverter power units

- Fiber optic bus parallel connection with Modbus-TCP communication for upper-level control

- Driving a 4000 kW motor with a total four-quadrant VFD installed capacity exceeding 4000 kW

This advanced setup ensures that the test bench can accurately simulate various load conditions for large marine engines, supporting both energy efficiency and operational stability.

Flexible Combination and Strong Redundancy

One of the key advantages of the GK980 multi-drive VFD is its modular parallel design. The system allows operators to flexibly select how many power units are engaged based on the motor load.

This flexible combination not only improves operational efficiency but also provides strong redundancy. If one power unit requires maintenance, others can continue operation without affecting the stability of the test bench. For high-power marine engine testing, this reliability is essential to ensure continuous operation and reduce downtime.

Compact Structure with High Stability

Another notable strength of the GK980 four-quadrant inverter is its compact and standardized cabinet design.

- Power units are designed with equal height and depth, simplifying integration.

- Both air-cooling and water-cooling options are available to meet different site conditions.

- Despite the 4000 kW capacity, the entire system maintains a compact footprint while delivering high stability.

This design allows for easier installation and long-term operation, making it suitable for large industrial test benches where space and reliability are critical.

Rich Expansion and Wide Compatibility

Modern test benches must integrate with various motors, encoders, and communication protocols. The GK980 multi-drive VFD is designed with broad compatibility:

- Motor types supported: asynchronous motors and synchronous motors.

- Encoder types supported: square wave, sine-cosine, resolver, and absolute encoders.

- Communication protocols: EtherCAT, Profinet, Modbus-TCP, Modbus-485, and CAN.

Through its parallel module architecture, the GK980 ensures seamless integration with upper-level supervisory systems and lower-level data acquisition systems. This makes it highly adaptable across different industrial environments, from marine engine test benches to heavy-duty industrial applications.

Greater Power and Wider Adaptability

As global shipping continues to demand higher efficiency, test benches must handle increasingly powerful engines. The GK980 multi-drive VFD meets this challenge by supporting:

- Up to 10 parallel power units with a total system power of 6000 kW.

- Multiple rectifier and inverter unit structures to match diverse site requirements.

This scalability and adaptability ensure that the GK980 can evolve with industry needs, making it a future-ready solution for marine propulsion testing, mining machinery testing, and other large-scale industrial test benches.

Conclusion

The application of the GK980 multi-drive VFD in a 4000 kW high-power engine test bench highlights its ability to deliver flexible combinations, compact design, broad compatibility, and high reliability. For industries that demand precise control, high redundancy, and scalable performance, the GK980 proves to be an ideal choice.

As shipping, energy, and industrial sectors continue to demand larger and more efficient engines, advanced multi-drive VFD systems like the GK980 will play an increasingly vital role in supporting innovation and ensuring sustainable operations.

Partner with GTAKE for Advanced VFD Solutions

At GTAKE, we specialize in delivering high-performance VFD systems for demanding applications such as marine engine testing, heavy-duty industrial machinery, and multi-drive high-power test benches. With advanced products like the GK980 multi-drive four-quadrant inverter, GTAKE provides:

- Flexible and redundant system design

- Compact and stable cabinet solutions

- Wide compatibility with motors, encoders, and communication protocols

- Scalable power capacity up to 6000 kW

Whether you are upgrading an existing test bench or developing a new high-power system, GTAKE’s VFD solutions can help you achieve higher efficiency, reliability, and cost savings.

Contact GTAKE today to learn more about how our GK980 multi-drive VFD can optimize your high-power testing and industrial applications.