In modern electrical and industrial systems, frequency converters quietly play a critical role in keeping equipment running smoothly. Whether it is adapting machinery designed for different grid standards or ensuring motors receive stable power, frequency conversion is essential. At this decision point, many engineers and buyers face a common question: should they choose a static frequency converter or a rotary frequency converter?

To answer this clearly, this article provides a practical and fact-based comparison of both technologies, explaining how they work, where they perform best, and how to select the right solution for real-world applications.

Understanding Frequency Converters in Practical Terms

Before comparing technologies, it is important to understand what a frequency converter does. A frequency converter changes the frequency of electrical power, typically between 50 Hz and 60 Hz, or adapts single-phase and three-phase systems. As a result, equipment can operate correctly even when the local power supply does not match its original design.

In industrial settings, frequency converters are widely used for motors, pumps, compressors, test benches, and imported machinery. Therefore, choosing the right type directly affects performance, reliability, and long-term operating cost.

What Is a Static Frequency Converter?

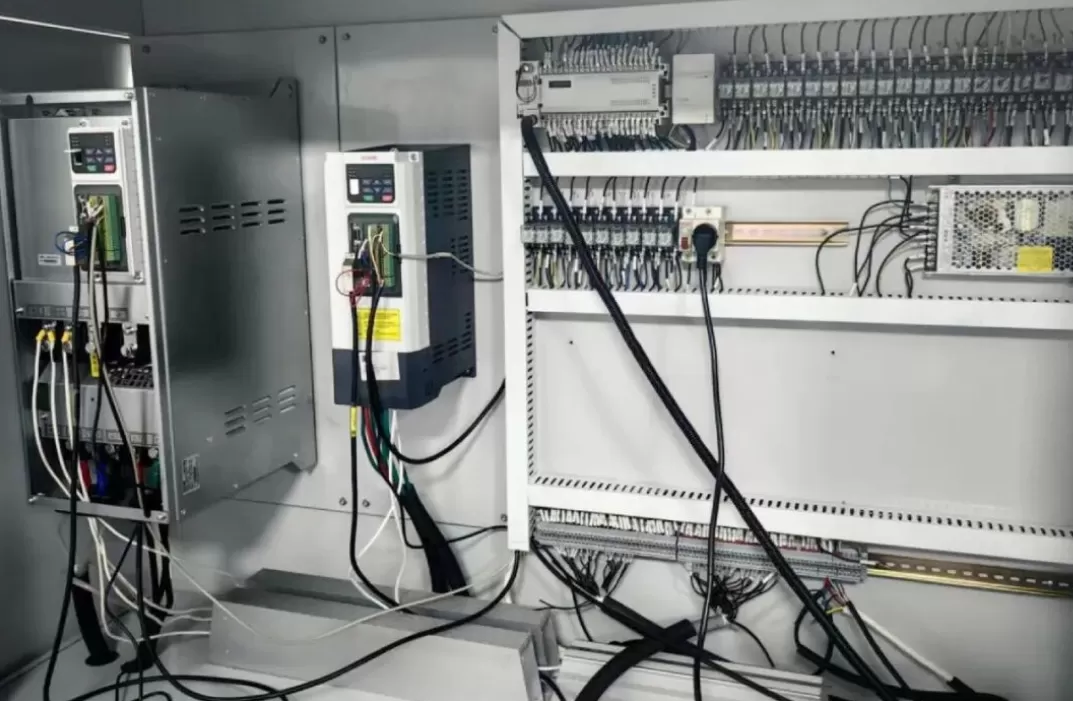

To begin with, a static frequency converter performs frequency conversion using electronic components only. There are no moving parts in the power conversion path, which clearly distinguishes it from rotary systems.

How a Static Frequency Converter Works

From a technical perspective, a static frequency converter follows a three-step process. First, incoming AC power is converted into DC through rectification. Next, the DC power is stabilized within a DC link. Finally, an inverter converts the DC back into AC at the required output frequency and voltage.

Because this entire process relies on solid-state devices such as IGBTs and power transistors, the conversion is fast and precise. As a result, static frequency converters offer accurate frequency control in a compact structure.

Key Features and Applications

In practice, static frequency converters are known for:

- High electrical efficiency

- Compact size and low noise

- Minimal mechanical wear

Due to these characteristics, they are commonly used in light-to-medium load applications. Typical examples include aviation ground support equipment, laboratory testing systems, and controlled manufacturing environments where frequency accuracy is critical.

However, while static systems excel in precision, they are generally limited in handling large inrush currents and sudden load fluctuations.

What Is a Rotary Frequency Converter?

In contrast, a rotary frequency converter is an electromechanical system. Instead of electronic switching, it relies on physical rotation to achieve frequency conversion.

How a Rotary Frequency Converter Works

Structurally, a rotary frequency converter combines an electric motor and a generator mechanically coupled, typically via a shared shaft or belt drive. The input power drives the motor, which mechanically turns the generator. The generator then produces output power at the desired frequency.

Thanks to the rotating mass, this system naturally provides inertia. As a result, it can absorb sudden load changes and maintain stable output even under demanding conditions.

Key Features and Applications

From an application standpoint, rotary frequency converters are valued for:

- Strong overload and inrush current capability

- Stable and balanced three-phase output

- High tolerance for load variation

For these reasons, they are widely used in heavy-duty industrial environments, such as CNC machining centers, large pumps, compressors, and legacy manufacturing systems where power stability is essential.

That said, rotary converters require more space, involve mechanical wear, and demand regular maintenance compared to static systems.

Static vs. Rotary Frequency Converters: A Practical Comparison

To make the differences clearer, it helps to compare both solutions from an engineering and operational perspective.

Output Stability and Power Quality

On one hand, static frequency converters provide precise electronic control but can be sensitive to rapid load changes. On the other hand, rotary frequency converters deliver naturally balanced output due to their mechanical inertia, making them suitable for equipment sensitive to voltage imbalance.

Load Handling and Starting Performance

When it comes to load adaptability, rotary converters have a clear advantage. They handle high starting currents and fluctuating torque with ease. Static converters, by comparison, are better suited for steady loads with predictable demand.

Efficiency and Energy Loss

In terms of pure electrical efficiency, static frequency converters typically perform better. Rotary systems experience mechanical losses due to rotation, although they compensate with excellent operational stability in harsh conditions.

Maintenance and Service Life

Static converters benefit from having no moving parts, which reduces mechanical wear. Rotary converters, while mechanically complex, can operate reliably for many years when properly maintained.

Installation and Footprint

Finally, static frequency converters are compact and easy to integrate. Rotary converters require more space, stronger foundations, and higher installation effort.

Which Converter Is Better for Heavy and Variable Loads?

For applications involving large motors, frequent starts, or sudden load changes, rotary frequency converters remain a reliable choice. Their mechanical inertia allows them to handle demanding conditions without destabilizing the power output.

In contrast, static frequency converters are better suited for applications where load conditions are stable and frequency precision is more important than surge capacity. This distinction is especially important when planning long-term system reliability.

Can a Variable Frequency Drive Be a Better Alternative?

At this point, it is worth considering a modern solution that often replaces traditional frequency converters: the Variable Frequency Drive (VFD).

Unlike conventional converters, VFDs not only adjust frequency but also control motor speed and torque in real time. As a result, they provide soft starting, smooth acceleration, energy savings, and reduced mechanical stress.

In many industrial motor-driven applications, a VFD-based solution can eliminate the need for separate frequency conversion equipment. Therefore, when evaluating static and rotary frequency converters, it is practical to also assess whether a VFD offers a more efficient and flexible solution.

Key Factors to Consider When Selecting a Frequency Conversion Solution

To make a well-informed decision, engineers and buyers should evaluate:

- Load type and rated power

- Starting current and duty cycle

- Required power quality and stability

- Installation space and maintenance capability

- Energy efficiency and total lifecycle cost

By considering these factors together, users can avoid oversizing equipment and reduce long-term operational risk.

Conclusion: Making the Right Choice for Your Application

In summary, static frequency converters are compact, efficient, and precise, making them suitable for controlled environments and moderate loads. Rotary frequency converters excel in heavy-duty applications where load stability and robustness are essential. Meanwhile, modern VFD solutions often provide a more advanced alternative for motor-driven systems.

The best choice depends not on technology alone, but on the specific operational requirements of the system.

Partner with GTAKE for Reliable Drive Solutions

Choosing the right frequency conversion solution requires both technical understanding and practical experience. GTAKE, as a professional variable frequency drive supplier, offers advanced motor drive and frequency control solutions for industrial and electric mobility applications.

With a strong focus on system reliability, energy efficiency, and application-specific design, GTAKE supports customers in selecting and optimizing the most suitable drive solutions.

If you are evaluating frequency converters or exploring modern VFD-based systems, GTAKE is ready to help you build a stable, efficient, and future-ready power solution.