For many die casting manufacturers, electricity cost accounts for a large share of total production expenses. As one of the main energy-consuming devices in a plant, the die casting machine is often called a “power eater.” Therefore, reducing energy consumption has become an important way for die casting factories to lower production costs and improve competitiveness. This is where using a VFD in die casting machines brings clear economic value.

1. High Energy Consumption in Die Casting and the Need for VFDs

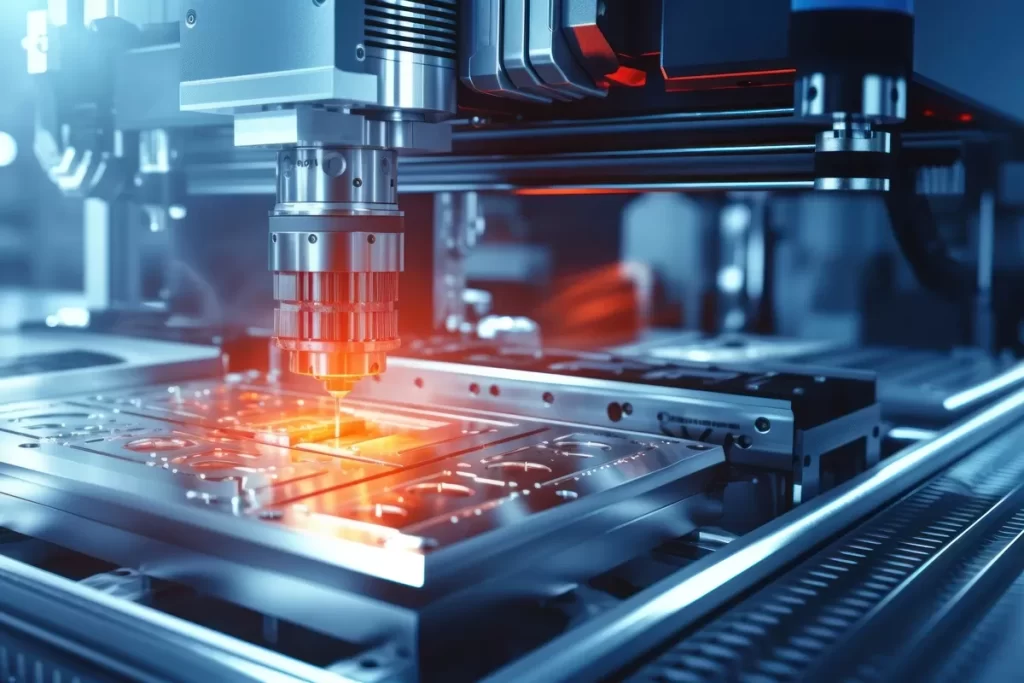

To begin with, most die casting machines in the industry use hydraulic transmission systems. The system relies on an electric motor to drive an oil pump, supplying power for all actions of the machine. During each casting cycle, the required hydraulic pressure and flow vary across different process stages. Traditional machines use throttle valves and pressure valves to adjust these needs.

However, because conventional systems mostly rely on a fixed-displacement pump, the motor delivers constant power regardless of the actual load. Any extra energy is wasted through overflow, leakage, and heat generation. This not only increases power consumption but also leads to high oil temperature, noisy operation, and shorter mechanical life. In many cases, motors are oversized compared to the actual requirement, causing even more unnecessary energy waste. As a result, using VFDs in die casting machines is an effective way to improve energy efficiency.

2. How Die Casting Cycles Affect Energy Use

To understand why VFD control makes a difference, it helps to look at the die casting process.

The mold-closing and opening stages require low pressure and short duration. By contrast, injection, holding pressure, and cooling stages require higher pressure and longer duration—often 40% to 60% of the entire cycle. These variations depend on the product size, weight, and material. Even on the same machine, changing the product often means different pressure curves and cycle durations.

Without variable control, a fixed-speed motor continues to run at full output during all stages. This mismatch between demand and actual output is the root cause of energy waste in traditional systems.

3. How VFDs Improve Hydraulic System Efficiency

At this point, the value of applying a VFD becomes clear. A VFD adjusts the motor speed according to the required pressure and flow. Since the oil pump output is directly related to motor speed, this allows the hydraulic system to operate based on real-time needs instead of outputting maximum power at all times.

Through the control system and feedback from pressure sensors, the VFD maintains stable pressure during key stages such as injection and holding. During low-demand stages like mold opening, the motor automatically slows down, greatly reducing energy use without affecting process performance. This shift from “constant output” to “on-demand supply” is the core advantage of VFD applications in die casting machines.

4. Key Advantages of Using VFDs in Die Casting Machines

4.1 Significant Reduction in Power Consumption

The most direct advantage is energy savings. Because the motor runs only at the necessary speed, energy waste from overflow and throttling is cut dramatically. Many manufacturers experience noticeable reductions in electricity bills after VFD retrofitting.

4.2 Lower Oil Temperature and Improved System Stability

Another benefit is the reduction in heat generation. When overflow is minimized, the oil temperature becomes more stable. This helps reduce hydraulic oil aging, leakage, and system instability.

4.3 Lower Noise and Longer Equipment Life

As the motor runs at lower speeds during non-critical stages, oil pump wear decreases, noise levels drop, and mechanical components last longer. This contributes to lower maintenance costs and improved machine reliability.

4.4 Improved Power Factor and Reduced Grid Impact

VFDs naturally improve the power factor of the system and reduce reactive power loss. Because soft start is built in, the impact on the power grid during machine startup is greatly reduced. This also helps avoid overloading transformers and extends the life of power equipment.

5. Practical VFD Performance Across Die Casting Stages

To see how VFDs improve performance throughout the process, we can look at specific stages:

Mold Closing / Opening:

Low pressure and short duration → Matches flow demandto save energy.

Injection Stage:

High pressure and fast response → VFD ensures stable output for precision control.

Holding Pressure Stage:

Medium speed for stable pressure to improve product consistency.

Cooling Stage:

Lower demand → motor automatically slows down, reducing power use.

These adjustments happen continuously and automatically, improving both efficiency and product quality.

6. Overall Economic Benefits of VFD Retrofitting

In the long run, the economic value of installing a VFD is clear. Energy consumption drops significantly, maintenance costs decrease due to lower wear, and the hydraulic system becomes more stable. Oil life is extended, component failures are reduced, and the machine becomes more efficient across different product types. For many factories, the improvement in production stability is as important as the energy savings themselves.

7. Key Considerations for VFD Installation

To ensure a successful upgrade, proper selection and tuning are essential. Motor power, pump type, and pressure requirements must be correctly matched to the VFD. Important parameters such as PID settings, pressure curves, and motor limits must be well adjusted. Installation details—including wiring, grounding, and cooling—also affect long-term reliability. When implemented correctly, VFDs deliver both energy savings and process control improvements.

Conclusion

The application of VFDs in die casting machines provides a practical and effective solution for reducing energy consumption, improving hydraulic performance, and lowering operating costs. By replacing constant-speed operation with demand-based control, die casting manufacturers benefit from higher efficiency and greater production stability.

For businesses looking to upgrade their equipment with reliable power control solutions, GTAKE offers advanced VFD products and professional technical support. As an experienced VFD drive supplier, GTAKE continues to help manufacturers improve energy efficiency and achieve stable, sustainable production.