In the ever-evolving landscape of electric vehicle (EV) technologies, motor control plays a critical role in delivering a smooth, efficient, and reliable driving experience. Among various control strategies, Field-Oriented Control (FOC) has emerged as the industry standard for high-performance EV motor control systems. This article explores the principles, advantages, and applications of FOC in modern EV motor controllers, with insights into how GTAKE integrates this technology into its solutions.

What Is Field-Oriented Control (FOC)?

To understand how FOC supports modern EV applications, it’s important to first grasp its core principle.

FOC, also known as vector control, is a method of controlling AC motors by decoupling torque and magnetic flux. It transforms the stator currents into a rotating reference frame aligned with the rotor’s magnetic field. By doing this, it becomes possible to control torque directly and precisely, similar to how torque is managed in DC motors.

Unlike traditional scalar control methods, FOC enables smoother and more dynamic performance, making it particularly suitable for electric vehicles where wide speed ranges and high torque at low speeds are required.

How FOC Works in EV Motor Controllers

To operate a three-phase electric motor efficiently, the motor controller must generate stator flux that remains perpendicular to the rotor flux. FOC achieves this through a series of mathematical transformations and control loops.

The process begins by converting the three-phase stator current (Ia, Ib, Ic) using the Clarke and Park transforms, which shift the current into a two-axis (d-q) rotating reference frame. In this frame, the ‘d’ axis controls magnetic flux, and the ‘q’ axis manages torque.

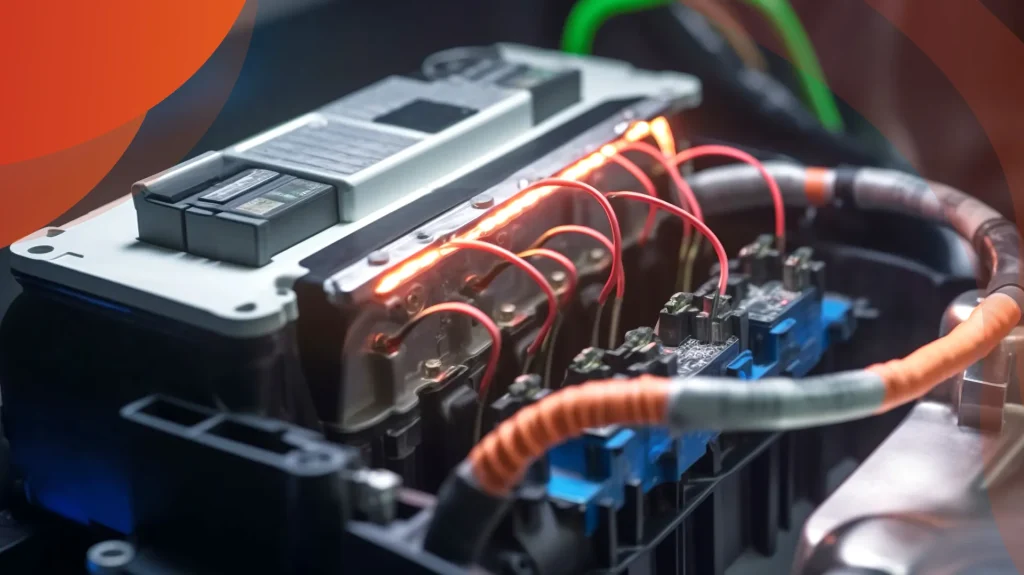

Key components in an FOC system include:

- Three-Phase Inverter: Supplies the motor with modulated AC voltage via PWM signals.

- Position Sensor or Estimator: Determines the rotor’s position, which is critical for aligning the stator current.

- PID Controller: Regulates current in both d and q axes by comparing feedback with reference values.

- Inverse Park Transform: Converts the controlled d-q voltages back to the three-phase system.

- Space Vector Modulation (SVM): Generates the final PWM signals to control the motor inverter.

Through this closed-loop control process, the motor receives optimized voltage and current, resulting in improved responsiveness and stability.

Advantages of FOC for EV Applications

The benefits of FOC make it especially well-suited for electric vehicle powertrains. These include:

- High Efficiency: FOC maintains efficiency across a wide speed range by controlling torque and flux independently.

- Fast Dynamic Response: Ideal for frequent start-stop driving conditions and sudden load changes.

- Quiet Operation: Smoother control of current results in reduced motor vibration and noise.

- Torque Accuracy: Critical for energy regeneration, precise acceleration, and enhanced safety in EV systems.

These advantages help meet the demanding requirements of both performance EVs and urban electric mobility solutions.

Application Scenarios in Different EV Types

FOC is a versatile control strategy that supports various electric vehicle configurations:

- Electric Motorcycles benefit from FOC’s compact implementation and quick torque response, ensuring agility and ride comfort.

- Battery Electric Vehicles (BEVs) utilize FOC to maximize driving range, especially at low speeds where high torque is essential.

- Hybrid Electric Vehicles (HEVs) require seamless coordination between internal combustion engines and electric motors, which is enabled by FOC’s precision.

In each case, FOC provides a consistent and scalable control foundation, making it ideal for manufacturers seeking efficiency without compromising drivability.

Challenges and Optimization Strategies

Despite its advantages, FOC implementation presents certain technical challenges:

- Sensor Accuracy: Accurate rotor position feedback is essential for proper alignment.

- Computational Load: FOC requires real-time mathematical computations, necessitating high-speed microcontrollers.

- System Tuning: Parameters must be carefully tuned for different motor types and vehicle platforms.

GTAKE addresses these challenges through advanced control algorithms, sensorless FOC options, and real-time auto-tuning features, enabling reliable performance across diverse applications.

The Future of FOC in Intelligent EV Systems

Looking ahead, FOC will continue to evolve alongside EV technologies. Its integration with AI and machine learning will allow adaptive motor control that responds to driver behavior and road conditions. Furthermore, over-the-air (OTA) updates will enable continuous improvement of FOC algorithms, optimizing energy usage and extending motor lifespan.

As EVs move toward greater intelligence and autonomy, FOC will remain a foundational technology for precise and efficient propulsion control.

Conclusion

Field-Oriented Control has become a cornerstone of modern EV motor control due to its ability to precisely manage torque and flux, resulting in smoother, quieter, and more efficient electric drives. At GTAKE, we leverage advanced FOC techniques in our EV Motor Control Units to support high-performance electric and hybrid vehicles.