Hydraulic transmission systems play a vital role in modern industrial applications by using fluid pressure to transmit power. They are known for their large output force, precise control, and smooth transmission performance. These systems are widely used in engineering machinery, aerospace, and industrial equipment. Especially in heavy-duty applications that require high power, precision, and reliability—such as pipeline systems in the petroleum and chemical industries or loader systems in the heavy transportation sector—hydraulic systems ensure stable and efficient operation.

The Role of Solenoid Valve Groups in Hydraulic Systems

In a hydraulic transmission system, the solenoid valve group serves as both the “nervous system” and the “execution terminal.” It bridges the gap between electrical control and hydraulic actuation, converting control signals into accurate and powerful physical actions. The performance of the solenoid valve group directly affects the response speed, stability, and safety of the entire hydraulic system.

To maintain consistent accuracy and reliability, solenoid valve groups must undergo periodic calibration and testing on dedicated test benches. These test benches simulate real operating conditions and verify parameters such as pressure response, flow rate, and leakage performance. Reliable control of the oil pump and hydraulic station during testing is therefore essential—and this is where the GS680 electro-hydraulic servo drive plays a key role.

GS680 Electro-Hydraulic Servo Drive in Solenoid Valve Test Benches

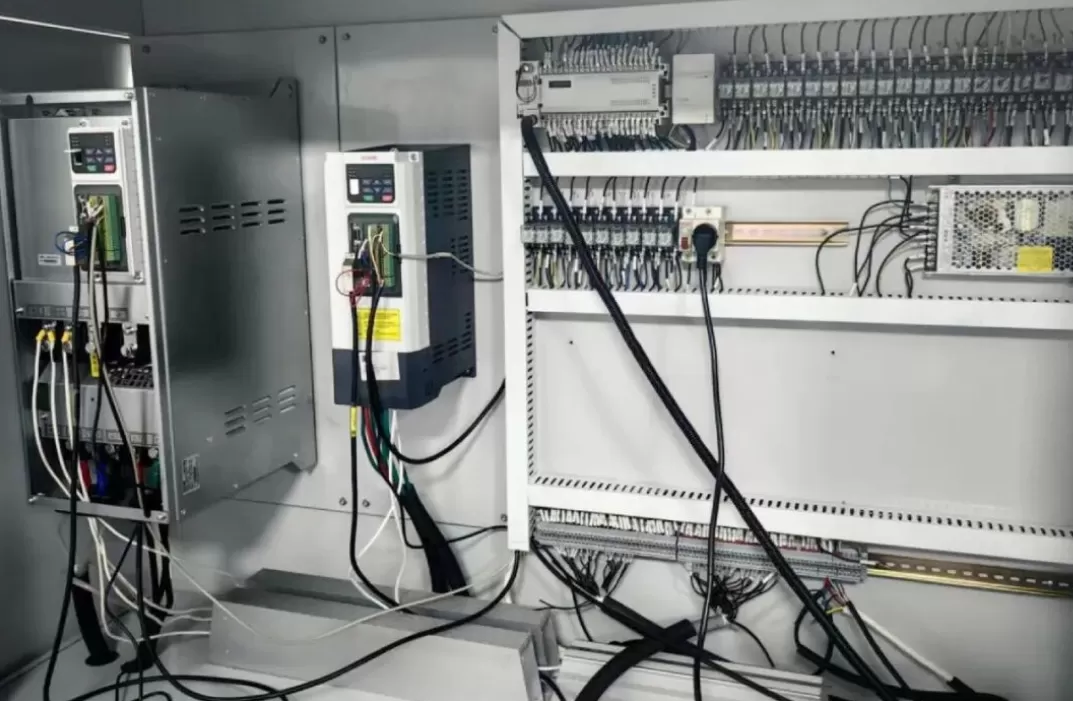

In this application case, two GS680 electro-hydraulic servo drives are used to control two oil pump systems with rated powers of 75 kW and 18.5 kW, respectively. The larger pump is designed for high-flow solenoid valve testing, while the smaller one handles low-flow precision tests. Together, they form a complete test bench system capable of covering a wide range of testing requirements.

The GS680 precisely controls the speed and torque of the servo motor, thereby ensuring stable and accurate oil pressure supply to the test bench. By maintaining smooth pressure transitions and avoiding fluctuations, it allows engineers to simulate various working conditions and ensure that each solenoid valve group meets its performance specifications.

This configuration not only enhances the testing accuracy but also significantly improves the reliability and safety of the testing process.

Key Advantages of the GS680 in Hydraulic Applications

1. Integrated System with Strong Adaptability

The GS680 integrates the oil pump, servo motor, and drive unit into a complete package, simplifying model selection and installation. This level of integration makes the system easier to deploy in different test bench environments and reduces the risk of parameter mismatches. The modular design also ensures high system efficiency and convenient maintenance.

2. Compact Structure and High Stability

Designed in a book-style compact form, the GS680 can be easily installed in standardized control cabinets. This saves space while maintaining excellent heat dissipation and vibration resistance. The robust design supports continuous operation under demanding industrial conditions, ensuring long-term reliability of the solenoid valve group test bench.

3. Wide Compatibility and Rich Extension Options

The GS680 supports multiple motor types, including asynchronous and synchronous motors, allowing for flexible adaptation to different hydraulic systems. It is also compatible with various encoder types such as square wave, sine/cosine, resolver, and absolute encoders.

In addition, the GS680 supports multiple industrial communication protocols—EtherCAT, Profinet, Modbus-TCP, Modbus-485, and CAN—enabling seamless connection with upper-level control systems and lower-level data acquisition devices. This high level of interoperability makes it an ideal solution for complex testing platforms.

4. High Protection Level and Flexible Application

With an IP20 protection rating, the GS680 can handle a variety of industrial environments and process requirements. It can be configured according to specific testing conditions, ensuring that it performs reliably in temperature-controlled labs or heavy-duty industrial sites.

Enhancing Testing Efficiency and Accuracy

By integrating the GS680 electro-hydraulic servo drive into the test bench, engineers can achieve real-time pressure control, smooth dynamic response, and stable flow output. These capabilities are crucial when testing solenoid valve groups that require rapid switching between high and low pressures.

Moreover, the drive’s precise torque control and fast feedback loop ensure that each test condition remains consistent and repeatable. This not only improves testing accuracy but also reduces downtime and system wear, extending the service life of the test bench components.

Conclusion

The application of the GS680 electro-hydraulic servo drive in solenoid valve group test benches demonstrates its outstanding performance in control precision, adaptability, and stability. Its integrated design, wide compatibility, and robust protection features make it a highly reliable solution for hydraulic system testing in demanding industries such as petrochemical, transportation, and heavy equipment manufacturing.

By ensuring accurate and stable pressure supply, the GS680 helps engineers validate and optimize solenoid valve group performance with greater efficiency and confidence.

As a professional inverter drive manufacturer, GTAKE provides advanced motion control and energy conversion solutions for industrial and automotive applications. With years of technical expertise and a strong focus on reliability, GTAKE continues to deliver innovative products that support precision control, energy efficiency, and system integration across a wide range of industries.